功能與技術

測試工作站

根據不同的應用領域,您可以在實驗室、維修間或手動測試台進行手動測試。半自動應用於製造業的典型測試場景,例如使用PE測試探頭。或者全自動整合到生產線上。

測試連接

對於不同類型的外殼可以配備一個測試插座和/或測試探頭的連接,以及設備前面板上的高壓測試槍的插座。如果需要,還可以在設備背面板增加額外的測試介面,如10芯測試插頭。有了這些,您可以連接通用接線盒、測試蓋或自動化系統的測試導線。

測試方法的切換

在ALL-IN-1測試設備中,內建的測試方法將自動切換到測試連接或測試探頭上。在測試開始之前,測試對象的所有電氣連接都可以連接到測試設備,以避免在每個單獨的測試步驟之後耗時手動切換測試導線。您的安全永遠是我們所重視的。

動態數據儲存

在內建記憶體可以儲存多達1000個測試規劃和測試結果,總計多達 790 個測試步驟。

測量技術

精確和快速測量,TRMS – 真實有效值測量,有效和峰值測量,有效和視在功率測量 ( cosφ) 。

設計

設備外殼 - 堅固的工業標準

由於其緊湊的½ 19”或19”工業外殼,GLP1-g可用於在最小的空間進行測試,同時充分利用可用的工作空間。

該設備堅固的可調式活腳確保它始終保持適當的位置。它還可以使用選購的安裝組件安裝在19”機櫃中。

功能選單

簡單而直觀--主選單

瀏覽設備設置是直接和簡單的:您可以靈活加載和自定義測試計劃,調整測試參數和改變設備的設置。

只需觸摸

測試設置在一個觸控螢幕上輸入。操作簡單明了,直接了當。

關於測試參數的細節

內建幫助功能為每個測試參數和設定值提供了詳細的解釋。

對所有測試條件進行合理性檢查

通過每次輸入後進行的內建合理性檢查程序,可確保輸入的每個測試參數或值都在測試設備的技術規格範圍內。以確保其結果是準確和可靠。

觸控顯示幕

螢幕顯示–讓一切盡在眼前

5”彩色TFT顯示幕在任何照明條件下(陽光或黑暗條件下)以出色的細節顯示所有測試步驟及其結果。

單一測試裝置的的視覺化

對於單一方法的裝置,測試結果可以用多種方式來描述。操作人員可以選擇他們習慣的視覺模式來查看測試結果。

多合一 ( ALL-IN-1) 測試裝置的視覺化

所有內置的測試步驟都是垂直排列。當前選擇的測試步驟以黃色突出顯示。在一個測試步驟結束時,它們會變成綠色(GO)或紅色(NOGO)。您也可以選擇一個全螢幕視圖,顯示每個測試步驟的細節。

儲存測試結果

以Excel格式存儲 - PrintCom 7

您可以使用PrintCom 7將測試結果以Excel格式直接儲存在連接的PC上。 PrintCom 7可讓您自定義創建一份可滿足公司內部需求的報告格式。通過RS232、USB或乙太網路將您的個人電腦與GLP1-g相連。

以CSV格式儲存 - PrintCom G2

您可以使用PrintCom G2將測試結果以CSV格式直接存儲在連接的PC上,讓您創建一個包含所有重要信息的完整測試報告。您可以通過乙太網路將您的PC與GLP1-g連接起來。

遠端控制

通過I/O進行通信

* 數位I/O, (輸入/輸出24V到PLC)

* 開始

* 停止

* 返回結果

* 以及更多...

通過RS232/USB/LAN和SCHLEICH通信協議進行通信

* 透由遠程加載測試計畫

* 傳輸帶有所有測試步驟和參數的測試計畫

* 啟動測試程序

* 接收測試結果

* 設置輸出

* 檢查輸入

* 以及更多...

通過LabView驅動程序進行通信

SCHLEICH-LabView驅動程式可使您的軟體與GLP1-g通信。

您可以加載一個測試計劃,啟動測試並接收測試結果。

特點概要

測量技術

* 精確的測量技術

* TRMS - 真實R.M.S.測量

PE/GB交流電阻

* 1 - 10, 1 - 30, 1 - 40, 1 - 75 A AC, 測試電壓可調,無損耗,電子控制

* 6/12 V AC,開路電壓可調

* 0 - 1.200 mΩ

* PE/GB電阻或電壓降

PE/GB直流電阻

* 1–40 A DC,可調測試電壓,電子控制

* 0–6Ω

絕緣電阻

* 50–1000 V DC,可調測試電壓,無耗損,電子控制

* 最大2 mA,安全電流限制

* 100 KΩ–10 GΩ

交流高壓

* 50–6000、100–12000、125–15000、250–30000、400–50000 Vac ,可調,無耗損,電子控制

* 高達200mA或帶有安全電流限制,高達3mA。

* 可實現斜坡電壓曲線。

* 峰值测量

功能測試

* 12 - 250 Vac,測試電壓可調,無耗損,電子控制

* 包括安全變壓器

* 可最大5 A測試

* cosφ

* 有效、無功和視在功率量測

* 最大1250 W,1250 VA,1250 VAR

* 包括L和N之間的短路測試。

一般

* 包括製造商的校准證書 (可追溯至國家標準 ) 。

* 內建時鐘和日曆

* USB、LAN和RS232

Key-Facts

- safety testers ALL-IN-1

- world’s smallest safety test instrument with this power density

- all test methods fully electronically controlled wear-free

- automatic switching between test methods and test connections

- fully automatic, semi-automatic or manual test sequence

- fully automatic or manual high voltage adjustment via rotary wheel

- operation via intuitive touch display

- LabView driver

- on table or mobile device in caddy

- 19″ rack for automation

- integrated test result memory

- traceable factory calibration certificate included

- safe according to EN50191

- PLe, SIL3, Kat4 Safety circuit (depending on device variant and degree of risk)

- high process reliability

- remote control for automation

- digital potential-free 24 V inputs/outputs

- standard tester ex stock or very short delivery time

Description

Cutting-edge. Multifunctional. Compact.

The GLP1-g is designed to test electrical products and insulation systems of all kinds with just one device. Over 50 device configurations offer you solutions for a wide variety of testing tasks and will therefore also fulfill special application requirements.

GLP1-g test devices are ideally equipped for applications in manufacturing, laboratories, test fields, QA, automation and many more. The customized configuration of features lets you accomplish your business goals in an efficient, reliable and safe manner.

Discover a previously unattained level of performance in this class of devices. The enhanced model of the popular and proven GLP1 test device lets you create your custom test plans and store results directly in the device. A multitude of new features such as the impressive new 5″ touch display do not leave anything to be desired.

Our engineers only apply state-of-the-art technologies in our testers. As early as 1995, we became the first manufacturer to equip our test equipment with user-friendly touch displays.

In keeping with our corporate policy, all hardware and software is developed in-house and manufactured entirely at our Sauerland facilities, eliminating the risks of long supply chains. SCHLEICH is a technological pioneer in modern high-voltage, safety and functional testing.

A carefully balanced product portfolio.

More than 50 device configurations offer test method combinations for a wide range of applications:

High voltage testers.

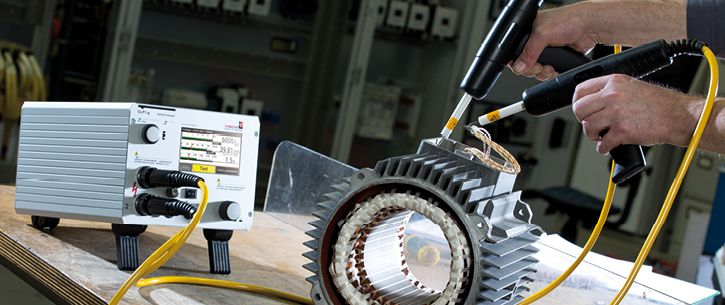

High voltage testing represents a common area of application. It can be performed manually with high voltage test probes or at higher voltages inside a test cover or a test cage. Integration into a fully automatic test line poses no problems either.

A typical manual test configuration using high voltage test probes.

High voltage testing in a test cage. The test object is connected to the output of the high voltage transformer e.g. via a copper band.

High voltage testing above 12 kV with automatic grounding.

High voltage testing in a steel spheres bath.

Technology

Functionalities & Technology

Testing workstations

Depending on the area of application, you can conduct tests manually in a laboratory, at a repair work station or at a manual test benches:

Semi-automatic application for typical testing scenarios in manufacturing, e.g. with PE test probes.

Fully automatic integration into a production line.

Test connections

Different types of housings can be equipped with a test socket and/or a connection for test probes as well as sockets for high-voltage test pistols on the front plate of the device. Additional test connections, such as a 10-pole test plug, can be added to the back of the device if required. With these you can connect e.g. a universal terminal box, a test cover or test leads for your automated systems.

Test methods switch-over

In an ALL-IN-1 test device, built-in test methods will be automatically switched over to the test connections or test probes. Before the start of a test, all electrical connections of the test object can be connected to the test device to avoid time-consuming manual switching of the test leads after each individual test step. Your safety always comes first.

Dynamic data storage

Up to 1,000 test plan configurations and test results for a total of up to 790 test steps can be stored in the built-in memory.

Measurement technology

Precise and fast measurements, TRMS – true R.M.S. measurements, effective and peak value measurements, effective and apparent power measurement cosφ

Design

Device housing – robust industrial standard

Due to its compact ½ 19″- or 19″ industrial housing, the GLP1-g can be used for testing in the smallest of spaces while making the most of the available working space.

The device’s sturdy adjustable feet make sure it always keeps its proper position. It can also be installed in a 19″ cabinet using an optional mounting kit.

Menu

Simple and intuitive – the main menu

Navigating the device settings is straightforward and simple: you can load and customize test plans, adjust test parameters and change the device’s settings.

Just a touch

Test settings are entered on a touch display. Handling is straightforward and direct.

Details regarding the test parameters

A built-in help feature offers a detailed explanation of each test parameter and set value.

Plausibility checks for all entries

With automatic plausibility checks performed after each input, you can be sure that each test parameter or value entered is within the technical specifications of the test device. The results are accurate and reliable test runs.

Touch display

On-screen display – keeping it all in sight

The 5″ color TFT display shows all test steps and their results in outstanding detail in any lighting conditions – in sunlight or darkness.

Visualization for test devices with one test method

For single-method test devices, test results can be depicted in a variety of ways. Operators can choose their preferred mode of visualization.

Visualization for ALL-IN-1 test devices

All built-in test steps are listed vertically. The currently selected test step is highlighted in yellow. At the end of a test step, they change to either green (GO) or red (NOGO). You can also select a full screen view with details displayed for each test step.

Storing test results

Storing in Excel format – PrintCom 7

You can store test results directly on a connected PC in Excel format using PrintCom 7. PrintCom 7 lets you create test reports in your own personalized corporate design. You can connect your PC to the GLP1-g via RS232, USB or Ethernet.

Storing in CSV format – PrintCom G2

You can store test results directly on a connected PC in CSV format using PrintCom G2, letting you create a matching test report containing all essential information. You can connect your PC to the GLP1-g via Ethernet.

Remote control

Communication via I/O

- digital I/O, (input/output 24 V to PLC)

- start

- stop

- return results

- and more …

Communication via RS232 / USB / LAN and SCHLEICH communication protocol

- loading test plans from the network

- transferring test plans with all test steps and parameters

- initiating test sequences

- receiving test results

- setting outputs

- checking inputs

- and much more …

Communication via LabView drivers

The SCHLEICH-LabView driver lets your software communicate with the GLP1-g.

You can load a test plan, initiate a test and receive test results.

Applications

Manual inspection

The GLP1-g tester is immediately ready to perform your measurements. By means of the unique manual mode, all integrated test methods may directly be applied. There is no need to generate a test sequence in advance! You only select the requested test method and start the test.

Similar to a multimeter, the test results are displayed on the tester´s screen. Thus, the detailed evaluation of your test object is immediately possible.

Even long-term analyses, with a duration of several hours, may be run in this operating mode.

Production| Semi-automatic inspection

Typical tests in production are either performed manually with test probes and/ or fully-automatic. Thanks to the convenient user guidance the GLP1 offers perfect testing conditions for these applications.

For the inspection of different kinds of test objects you can save up to 1000 test sequences in the GLP1-g, which can be opened and started by using the touch display.

Usually terminal boxes are used for connecting test object and tester.

We offer standard terminal boxes in 4 different designs.

Serial production| Fully-automatic inspection

The GLP1-g may be easily integrated in your production line. The tester´s dimensions are based on a ½ 19“- or 19“-housing, which means, that it perfectly fits in your plant. Additional, flexible interfaces allow an entire remote control. A connection to a master PC or a PLC may easily be established.

You can store up to 1000 test sequences for several test objects. They can be activated via interface and the test may immediately be started. All test results are accessible via this interface and may be stored by the master PC in a central database. Furthermore it´s possible to save the test results locally on the tester or in a computer network.

To achive an even higher level of flexibility in automation or to control more complex processes we alternatively recommend our GLP2-testers.

Regular function tests with black boxes

The proper function of the single tests has to be regularly inspected. For this, a blackbox is used. The tester has to precisely determine the blackbox´s measured results. Otherwise the tester is locked.

The control measurement may be based on a Go/ No Go-specification or on reference values with tolerance specification.

Features at a glance.

Measurement technology

- precise measurement technology

- TRMS – true R.M.S. measurements

PE/GB-resistance AC

- 1 – 10, 1 – 30, 1 – 40, 1 – 75 A AC, adjustable test voltages, free of wear, electronically controlled

- 6/12 V AC, adjustable open circuit voltage

- 0 – 1.200 mΩ

- PE/GB-resistance or voltage drop

PE/GB-resistance DC

- 1 – 40 A DC, adjustable test voltages, electronically controlled

- 0 – 6 Ω

Insulation resistance

- 50 – 1,000 V DC, adjustable test voltages, free of wear, electronically controlled

- max. 2 mA, security current limit

- 100 KΩ – 10 GΩ

High voltage AC

- 50 – 6,000, 100 – 12,000, 125 – 15,000, 250 – 30,000, 400 – 50,000 V AC, adjustable, free of wear, electronically controlled

- up to 200 mA or with security current limit up to 3 mA

- ramp-/voltage profile possible

- true effective value and peak value measurement

High voltage DC

- 50 – 4,000, 50 – 6,000, 1,000 – 10,000 V DC, adjustable, free of wear, electronically controlled

- up to 20 mA or with security current limit up to 10 mA

- effective and apparent power measurement

- ramp-/voltage profile possible

- peak value measurement

Function testing

- 12 – 250 V AC, adjustable test voltages, free of wear, electronically controlled

- safety transformer included

- max. 5 A

- cosφ

- effective, reactive and apparent power measurement

- max. 1,250 W, 1,250 VA, 1,250 VAR

- short circuit test between L and N included

Basics

- manufacturer’s calibration certificate, traceable to national standards included

- built-in clock and calendar

- USB, LAN and RS232